The efficiency of a plant or production facility is determined in part by the cleanliness and order of the facility. The 5S program was developed in Japan to educate employees and improve production plant order and cleanliness. The program has also been widely adopted in the west.

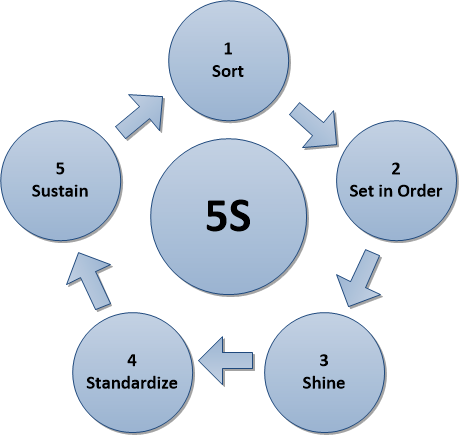

The components of the 5S program are:

- Sort (Seiri)

- Set In Order (Seiton)

- Shine (Seiso)

- Standardize (Seiketsu)

- Sustain (Shitsuke)

One popular variation of the program uses six components by adding Safety (although In Order could easily be interpreted to include Safety), while another variation only uses four components by combining Set In Order and Shine.

Henry Ford’s CANDO program pre-dates 5S and includes Cleaning Up, Arranging, Neatness, Discipline and Ongoing Improvement, although the two are likely unrelated.

Now you can start your own 5S program!